Our facilities

Our testing facilities

In-situ façade testing

The BEF (Façade Test Bench), located in Anglet, is designed for testing both opaque and transparent façade elements. Facing south, it consists of three identical cells equipped with heating, cooling, and air exchange systems.

The BEF is extensively instrumented, allowing for the monitoring of numerous parameters during test campaigns.

Examples of tests conducted include:

- INTUITHERM: thermochromic glazing

- VAPROSOL: glazing with solar protection

- ALUCLADDING: ventilated aluminum cladding façade

- E2VENT: an innovative ventilated façade

- IMMOBLADE: passive and seasonal solar protection

Air-water-wind tests for façade products

Located at COVERS, just 15 minutes from Bordeaux, this partnership test bench, operated by NOBATEK, offers the capability to conduct blank tests followed by qualifying tests supervised by the CSTB. It also includes a prototyping area with machining capabilities, allowing for mock-up adjustments between tests.

Features:

- Air-tightness, water-tightness, and wind-tightness tests

- Capacity to accommodate models up to 5m x 5m

- Fully digitized and automated test sequences and measurements

- Flexibility to select a usage period based on the estimated duration of the work

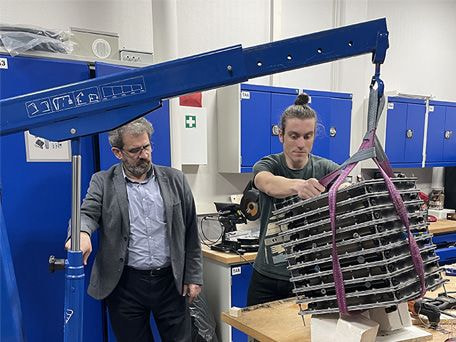

1:1 design prototyping areas

NOBATEK possesses the technical and human resources necessary to create prototypes of innovative technologies and to assess their performance in both controlled environments and real-world conditions. We utilize our facilities in Anglet and Bordeaux, as well as resources from our local ecosystem, which includes the ARKINOVA Activity Generator, the University of Bordeaux campus, the University of Pau, and the Pays de l’Adour. Additionally, we collaborate with partner technology centers that offer various tools such as CJP powder and FDM plastic 3D printers, programmable robots, 3D scanners, and software, among others.

RE and HVAC energy systems

Located in Talence, this platform is dedicated to testing and evaluating the energy performance of heating, ventilation, and air conditioning (HVAC) systems as well as renewable energy sources. It allows for the implementation of technological solutions in a representative environment across various levels of maturity, ranging from proof of concept to industrial products. The method for measuring performance can be integrated with a modeling and simulation approach to enhance the design and development process.

©Emmy Martens

Prototyping hall

The prototyping hall enables a transition from the material scale to the construction system scale. It is possible to conduct tests on component assemblies and the implementation of materials within systems (wall elements, roofing elements, etc.) on a real scale.

These construction systems can then be characterized using our test benches.

Test & evaluation equipment

Air Quality Laboratory

Physico-chemical tests

Materials Laboratory

Formulation tests, preparation of test specimens, characterisation of materials (ageing, thermal conductivity, etc.)

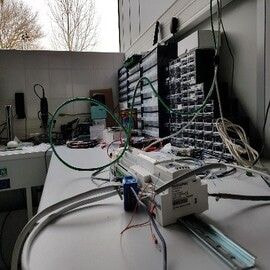

Metrology & monitoring laboratory

The process involves experimentation, configuration, calibration, and testing of instruments used to monitor building performance.